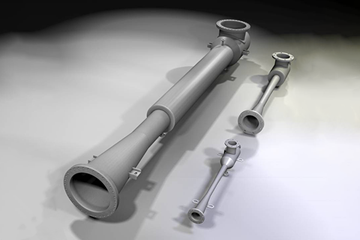

Vacuum Ejectors & Systems

Whether on their own or as part of a hybrid vacuum system, NASH steam jet and air ejectors have the ability to handle large volumes at deep vacuum levels. Ejectors and hybrid vacuum systems can be optimized to contribute to process enhancement and operational efficiency.

Vacuum and steam ejectors are simple in construction with no moving parts to wear or break. This makes them a reliable and low maintenance choice. Using steam as the high-pressure motive fluid to create deep vacuum with no limitations on size, capacity, or materials of construction steam jet ejectors are ideal for vacuum applications in the oil & gas, chemical, and electric power industries. Air jet ejectors are used when required capacity is low, or when steam is not desired or available. For large capacities and deep vacuum where steam isn't available or desired, other Gardner Denver Nash technologies can be used.

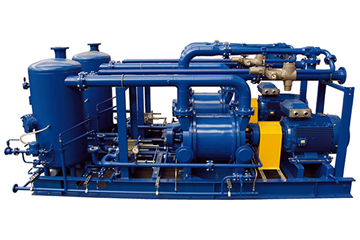

In a hybrid vacuum system, steam or air ejectors are combined with other vacuum technologies, including liquid ring vacuum pumps, boosters, and dry vacuum pumps. These systems are optimized for improved performance and efficiency while reducing greenhouse gas emissions. Improved efficiency means greater energy savings and a rapid payback of just 2 years or less on most NASH hybrid vacuum systems.

Since 1986, when Nash acquired the Kinema Corporation, we have designed and manufactured liquid ring ejector systems that combine ejectors with liquid ring and other vacuum technologies. NASH ejectors and hybrid vacuum systems are backed by a complete system warranty, and our global engineering, service, and technical support team.

我們可以如何幫助您?